In this blogpost series, I shall discuss on- Why the need for digitalization in pharma R&D labs?

Need for digitalization in pharma & medical device R&D:

Historically R&Ds regardless of industry sector, were run in an unstructured way. The degree or extent of ‘unstructured-ness’ is different for different industry sectors.

For example, R&D in a metallurgy firm is less sophisticated than in an engineering firm, while R&D labs in the electronic industry may be top class. Similarly, R&D labs in chemical industry, oil & gas industry may be more ‘unstructured’ compared to pharmaceutical or medical device R&Ds.

Then came an era of EVOP (Evolutionary Operations) and Experimental designs or Design of Experiments (DOE). This brought some structure to R&D’s workflow, yet not the desired finesse.

Scientists tend to record results in notebooks, spreadsheets, even on post-it (sticky) notes. Each scientist has his/her unique way of recording experiments, observations and results.

Data is usually decentralized and often buried under a pile of ad hoc experimentation, and this happens even in the most state-of-the-art laboratories. For example, pharma R&D labs have one of the most superior quality assurance norms to comply with. Yet when it comes to pharma R&D’s efficient data capture and data utilization, it has a long way to go!

This is one of the main reasons why pharma R&Ds run on high budget. I shall not take up hi-fi examples but simply put if a product can be developed with 20 experiments instead of 80, cost (of experimentation) will slash to around 1/4th. Now imagine if a product can be developed by mere few experimentations and no clinical trials? Wondering how’s that possible?

Yes, that’s possible- by digitalization!

R&D costs are skyrocketing, while ROI is steadily falling over the last decade. In 2010 the mean cost of bringing a new drug to market was US$1.1 billion ... in 2018 it was US$2.1 billion with clinical trials making up an increasingly large share of this cost. Meanwhile, the mean projected return on R&D investments fell from 10.1% in 2010 to 1.8% in 2019.

Digital transformation could reverse this trend of declining ROI in pharma R&D and improve R&D productivity over the next decade... What will it take to realize this potential?

A recent survey reported opinion of 250 global pharmaceutical and biotechnology leaders on the state of digitalization in biopharmaceutical R&Ds. It was found that some progress is being made, but that there was a greater-than-anticipated gap between the expected value of digital in pharma R&D and actions being taken to realize that value.

In the next part of this blogpost series, I shall discuss on- How to go for digitalization in pharmaceutical and medical device R&Ds.

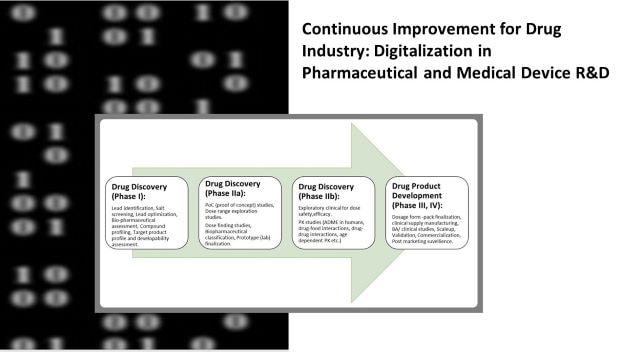

Meanwhile, note that there are fifteen different Continuous Improvement pathways for pharmaceutical and medical device R&Ds. Are you planning a Continuous Improvement initiative for your R&D division?

Upcoming blogposts in this series-

Part 4: Advantages of digitalization in pharmaceutical and medical device R&Ds.

Part 5: Digitalization in various phases of drug research and development.

Part 6: Selecting the right R&D digitalization platform.

Part 7: Six building blocks for digital transformation in pharmaceutical and medical devices R&D.

Part 8: How to transform existing R&D setup to a digitalized R&D.

Part 9: Tips and Quick wins of digitalization in pharmaceutical and medical device R&D.

Related reading:

#businessprocessimprovement #continuousimprovement #digitalization #digitization #digitaltransformation #digitalizationinpharmaceuticalR&D #digitalizationinmedicaldeviceR&D