|

Shruti is a Go-To Scientific Expert and Management Leader for-

|

SPECIALIZATION:

Shruti leads product development and operational excellence initiatives for organizations across various industry sectors such as:

- Life Sciences (Pharmaceuticals, MedTech, Biotech, Cosmetics).

- Chemicals.

- Healthcare & Biomedical research.

- Mining.

- Packaging.

- Transportation and Supply chain logistics.

- Oil & Gas.

She has a PhD (Tech) in Pharmaceutics, MBA, is a Certified Lean Six Sigma Black Belt and Kaizen coach. She has several publications in peer-reviewed scientific & management journals and 33 patents to her credit. Here are the details of Shruti's- Publications and Patents.

Shruti leads product development and operational excellence initiatives for organizations across various industry sectors such as:

- Life Sciences (Pharmaceuticals, MedTech, Biotech, Cosmetics).

- Chemicals.

- Healthcare & Biomedical research.

- Mining.

- Packaging.

- Transportation and Supply chain logistics.

- Oil & Gas.

She has a PhD (Tech) in Pharmaceutics, MBA, is a Certified Lean Six Sigma Black Belt and Kaizen coach. She has several publications in peer-reviewed scientific & management journals and 33 patents to her credit. Here are the details of Shruti's- Publications and Patents.

Achievements:

Shruti received the pioneer PAMDAL Young Pharmaceutical Scientist Award for her work on 'Patient Centric Drug Product Design'.

She is also referenced in Google Scholar ...

Expertise:

Leading Operational Excellence Initiatives:

Shruti improves Operational Efficiency by strategic use of-

Process design, Lean Manufacturing, Mistake-proofing products & processes, Operations management, Change management, installing a Culture of Quality, Employee engagement and Continuous improvement.

Achievement Dashboard:

Process Design Expertise:

Shruti employs Value Stream Mapping to business process(es) to discover flaws and gaps in as-is process. Based on the findings of the value stream study, she then designs a strategy and execution plan to overhaul or redesign the process(es) as needed, to generate increased profit. She employs business improvement methodologies such as- Lean, Kaizen, TQM, Just-in-Time, ISO, 5S, Lean Six Sigma, TRIZ, Hoshin Kanrii, QbD and TPM, to improve profitability from Research, Manufacturing and Service divisions and the business in entirety.

Over a span of a decade, Shruti has increased productivity and brought down cost in several organizations from life science, chemical, engineering and biotech sectors.

Over a span of a decade, Shruti has increased productivity and brought down cost in several organizations from life science, chemical, engineering and biotech sectors.

Here are few examples of Shruti’s success with increasing Productivity and Operational Efficiency-

|

|

Just-in-Time in a life science company for Business Turnaround-

Shruti employed Just in time (JIT) principles to R&Ds of pharmaceuticals, contract research organizations (CRO), natural product companies. Through flawless execution of JIT technique, Shruti succeeded in saving consumable expenses by 75-80 % which was a significant achievement towards lowering ‘overhead’ expenses for the organization. Checkout the full case study here |

|

ISO in HR department of chemicals and biotech company-

ISO is usually applied in operations, logistics and quality departments of chemicals and biotech plants. Shruti prepared the organization for ISO compliance audit and obtained certification in the first attempt. In addition, Shruti applied ISO in HR department to retain talented employees. As a result, this stopped employee turnover, cost associated with out-going employee as well as the cost of recruiting and training new hires. By applying ISO techniques in HR function, Shruti succeeded in 100% talented employee retention consecutively for 3 years, which saved over half a million dollars in aggregated cost. Shruti then extended ISO implementation to others functions of HR department such as- recruitment process, training process, annual goal setting, year-end performance evaluation, bonus schemes, employee-engagement process generating savings of over five million dollars each year for the company. |

|

Lean Six Sigma in CRAM operations-

Shruti applied Lean six sigma in service functions of a contract research and manufacturing (CRAM) company. This company had numerous customer complaints, short on deliveries as well as product quality problems. She applied Lean six sigma principles and reduced wastes in time, consumables, re-works, and defects. Within one year, she succeeded in eliminating product quality problems by 100%. She reduced customer complaints by 80% and delivery shortages by 70%. Additionally, she succeeded in procuring a repeat business of USD 30 million for the organization. |

|

Lean Kaizen in warehouse-

Shruti employed Lean principles to streamline inventories; reduce re-works, rejects and back orders which not only improved operational efficiency but also saved $200,000 annually. She also introduced a positive change in R&D work culture by successfully implementing Kaizen principles, which resulted in increased R&D productivity i.e. more formulations developed with less experiments. This not only reduced research costs but also improved overall R&D efficiency by 20%. |

|

Quality by design (QbD) in product development lab-

Shruti implemented QbD with Poka Yoke in pharmaceutical R&D, testing, clinical study, manufacturing, quality, warehouse, distribution & logistics and marketing functions. By employing QbD and Poka-Yoke in combination, Shruti succeeded in increasing R&D output by 25%, shortened development timelines by 40%, increased manufacturing capacities by 30%, reduced testing costs by 10%, completely eliminated product quality complaints and improved customer satisfaction by 15%. Shruti achieved these results by employing a strategically design QbD implementation process using ‘customer-centric innovation’ philosophy. Firstly, critical quality attributes (CQA) were assigned to incoming raw materials, machinery etc. She then prepared a target product profile, based on customer feedback (via surveys, interviews, complaints etc.). Later, the feedback was reviewed; root- cause analysis was conducted using Ishikawa and 5 Whys concept. Appropriate CAPA (corrective actions preventive actions) was put in place. All experiments were designed using the DOE (Design of experiment) principle and edge of failure determined using the FMEA (Failure mode effect analysis) model. Results from QbD implementation were further augmented by use of Lean and 5S with QbD, It reduced production back-orders by 35% and inventory wastes by 25%. |

|

TQM in bulk drug and formulation facility-

Shruti implemented TQM in bulk drug and drug product manufacturing facility. This reduced quality complaints by 50% and re-works by 15%. |

|

Kaizen for inventory management-

Shruti used Lean Kaizen to supply chain management functions viz. Purchase, negotiations, contracts, vendor development, vendor approval, vendor ratings, warehouse stocking (EOQ, ABC and VED analysis) and material requirement planning (Linear programming and MRP). |

Checkout more Case Studies on Kaizen, Lean Six Sigma, TQM, Just-in-time installations and Business Transformation here. |

Mistake-proofing and Operations Management Expertise:

Shruti employs FMEA, CAPA, Poka Yoke or Hoshin techniques to mistake-proof products and processes. She improves process capability to a statistical control of Cpk 1.5 or higher. With combined use of operations management and mistake-proofing techniques, Shruti re-balances manufacturing lines and service operations to cut costs, reduce cycle-times, back-orders, plug bottlenecks, increase capacity-utilization and reduce over-heads.

Shruti has improved operational efficiency for several manufacturing and service operations such as-

|

|

Manufacturing operations:

Service operations:

|

Change and Quality Management Expertise:

Shruti has over 17 years of hands-on expertise with facilitating start-ups and growing companies towards building 'Quality' and Quality-by-design (QbD) culture in their organization. She is hands-on with various change management tools such as 8D, Kotter, McKinsey, Bridges transition model, Lewin change models.

Through effective installation of quality management systems (QMS) Shruti has reduced rejects, defects, scrap and cut cost.

Through effective installation of quality management systems (QMS) Shruti has reduced rejects, defects, scrap and cut cost.

Shruti specializes in full spectrum of quality management comprising: |

|

Audit Expertise:

Shruti specializes in different types of Internal, External and Third party QUALITY AUDITS such as- Compliance audits, Special investigations/ Due diligence, Operations audits, Departmental reviews and Follow-up audits.

Shruti has conducted numerous Due Diligence and more than 500 Quality Audits across the globe, comprising-

|

|

Leading Innovation Management Initiatives:

Now more than ever, innovation is the key to growth, to acquiring and sustaining competitive advantage and to building shareholder value for long-term. An effective innovation strategy depends more on an organization’s innovation processes, tools and culture than how much it spends on R&D.

Shruti's innovation strategies customize client's innovation portfolio to their needs, reduce time-to-market revenues as well as help clients define the role of innovation in their pursuit of growth. She provides perspectives and tools on how to achieve strategic R&D objectives comprising- generic product development, market expansions, break-through innovations, strategic tie-ups, acquisitions, to rapidly translate 'Ideas to Profits'- Consistently !

Shruti's approach to Innovation Portfolio development begins by diagnosing the client’s current innovation processes & results and then helping them build distinctive capabilities to drive future performance that would bring right products to market FASTER.

Shruti has successfully Transformed existing R&D labs, built state-of-the-art R&D infrastructures and created customer-focused R&D capabilities for various industry sectors belonging to Manufacturing as well as Service Industry. Till date, Shruti has saved over $15M in Life Science R&D revenues.

Shruti has lead and successfully delivered 50 Innovation Management projects out of which 25 products were launched first-time in the world!

Further, Shruti's expertise with patenting and patent evaluations guides researchers to find ways to circumvent enforced patents and develop products that are not only 'Tough To Copy' but also create intellectual property assets for the company.

Check out here for details on Shruti's achievements with Innovation Management projects.

Shruti's innovation strategies customize client's innovation portfolio to their needs, reduce time-to-market revenues as well as help clients define the role of innovation in their pursuit of growth. She provides perspectives and tools on how to achieve strategic R&D objectives comprising- generic product development, market expansions, break-through innovations, strategic tie-ups, acquisitions, to rapidly translate 'Ideas to Profits'- Consistently !

Shruti's approach to Innovation Portfolio development begins by diagnosing the client’s current innovation processes & results and then helping them build distinctive capabilities to drive future performance that would bring right products to market FASTER.

Shruti has successfully Transformed existing R&D labs, built state-of-the-art R&D infrastructures and created customer-focused R&D capabilities for various industry sectors belonging to Manufacturing as well as Service Industry. Till date, Shruti has saved over $15M in Life Science R&D revenues.

Shruti has lead and successfully delivered 50 Innovation Management projects out of which 25 products were launched first-time in the world!

Further, Shruti's expertise with patenting and patent evaluations guides researchers to find ways to circumvent enforced patents and develop products that are not only 'Tough To Copy' but also create intellectual property assets for the company.

Check out here for details on Shruti's achievements with Innovation Management projects.

Leading Product Development Programs:

Shruti leads product development programs for Pharmaceuticals, Medical Devices, Nutraceuticals, Cosmetics, Biotech, Food and Healthcare R&Ds.

Shruti is go-to Expert on 'How to Research?'

Till date Shruti has saved over $55M in R&D revenues.

Shruti strategically combines 'research tools' with specially customized 'continuous improvement tools' for product development to develop cost-effective, quality products. This increases R&D productivity, saves costs and speeds-up product launches.

Shruti strategically combines 'research tools' with specially customized 'continuous improvement tools' for product development to develop cost-effective, quality products. This increases R&D productivity, saves costs and speeds-up product launches.

Shruti uses strategic QBD to improve R&D productivity as well as business resilience-

Shruti's Pharmaceutical Product Development Expertise-

Shruti leads path-breaking drug product development programs such as Complex Generics, Specialty Pharmaceuticals, Medical Devices, Nanotechnology-based and Targeted Drug Delivery Systems.

Some of the cutting-edge formulation projects Shruti spearheads are: Dermatologicals, Ophthalmics, MUPS, Nasal gels, Dry powder inhaler capsules, Dry powder inhaler device, Effervescent & Chewable tablets, ODT, Oral rehydration salts, taste-masked pediatric syrups, Large volume parenterals, 3D Printed formulations, Nanotech-based time-release drug delivery, Colon-targeted dosage forms.

Shruti integrates her proficiency in patient-centric product design, patent evaluation, QbD, Agile and Kaizen to improve pharmaceutical R&D processes, productivity and profitability. Her mantra is to shorten development timelines, build lean processes and launch products fast-to-market.

Besides leading formulation programs, Shruti specializes in Continuous Improvement for R&D, designing state-of-the-art R&D facility, pilot plant, manufacturing sites and testing labs, Quality management systems, Improving R&D productivity and Mistake-proofing processes. More >>

Shruti has received numerous industry awards such as- Young Scientist Award, IDMA Research Awards, DSIR (Department of Scientific and Industrial Research Govt. of India) Scholarship etc. Check out Shruti's Hall of Fame.

Shruti has 33 patents to her credit (Canada, India and PCT filings). Check out Shruti's List of Patents.

Shruti leads path-breaking drug product development programs such as Complex Generics, Specialty Pharmaceuticals, Medical Devices, Nanotechnology-based and Targeted Drug Delivery Systems.

Some of the cutting-edge formulation projects Shruti spearheads are: Dermatologicals, Ophthalmics, MUPS, Nasal gels, Dry powder inhaler capsules, Dry powder inhaler device, Effervescent & Chewable tablets, ODT, Oral rehydration salts, taste-masked pediatric syrups, Large volume parenterals, 3D Printed formulations, Nanotech-based time-release drug delivery, Colon-targeted dosage forms.

Shruti integrates her proficiency in patient-centric product design, patent evaluation, QbD, Agile and Kaizen to improve pharmaceutical R&D processes, productivity and profitability. Her mantra is to shorten development timelines, build lean processes and launch products fast-to-market.

Besides leading formulation programs, Shruti specializes in Continuous Improvement for R&D, designing state-of-the-art R&D facility, pilot plant, manufacturing sites and testing labs, Quality management systems, Improving R&D productivity and Mistake-proofing processes. More >>

Shruti has received numerous industry awards such as- Young Scientist Award, IDMA Research Awards, DSIR (Department of Scientific and Industrial Research Govt. of India) Scholarship etc. Check out Shruti's Hall of Fame.

Shruti has 33 patents to her credit (Canada, India and PCT filings). Check out Shruti's List of Patents.

To learn more, consult with Shruti or book a workshop, seminar. Contact via Form or WhatsApp 1.403.969.6219

|

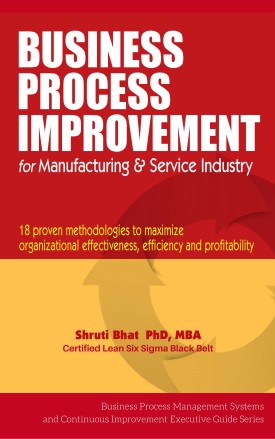

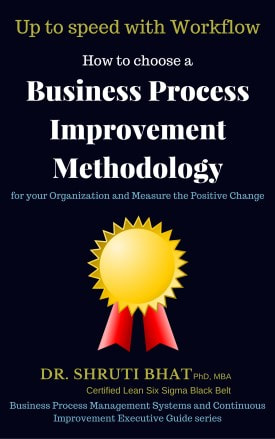

Shruti's best-selling paperbacks …

|