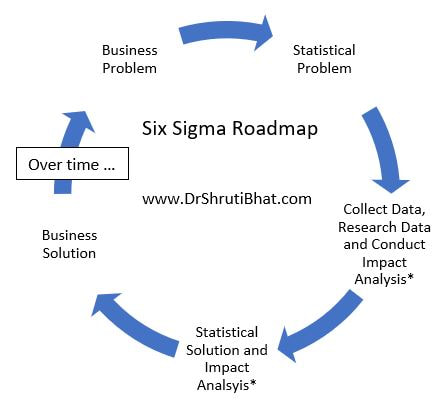

So, let’s get started …

Six Sigma can be applied to service industry. Though, variety of engagements faced by service firms makes it more difficult to apply Six Sigma. Yet Six Sigma methodology has been successfully applied in service sectors be it airlines, health care, banking, restaurant chains, IT, call center management, etc.

One of the biggest challenges to applying Six Sigma in a service industry is high number of variations than a standard product manufacturing process. This is because, service quality is ‘perceived’ by an individual, as against ‘use’ of a standard product.

One may not require applying all Six Sigma tools to all service process. For example Minitab application is un-necessary for a service process improvement. However, the general concept of Six Sigma can certainly be applied successfully.

Hence, metrics score of 3.6 million or lesser defects per million opportunities is efficiently achievable for manufacturing processes rather than service processes.

In addition, the return on investment (ROI) achieved from a Six Sigma service process, usually, has been found not worth the input cost for the transformation.

Service industries usually aim lower than 3.6 million dpmo metric score. The Cost–Need quotient is often evaluated prior to rebalancing the existing process to a 3.6 million dpmo level.

To clarify this point, let me take example of two important processes within Air transportation service industry- the first one is, landing gear assembly-operation for planes, while second one, is correct passenger bag arrivals at destination, on time.

The first process has to be a complete Six Sigma process i.e. with less than or equal to 3.6 million dpmo score, since, any failure of landing-gear operations can result in a plane crash catastrophe!

As regards the second process- i.e. passenger bag arrivals, one needs to check out what is the level of existing process on a sigma scale. Then calculate costs involved for transformation, its impact on business, potential loss of business due to unsatisfied customers, etc. and decide appropriately. Usually airlines follow 3- sigma level for baggage handling processes.

In my decade-long experience as a successful Continuous Improvement consultant, Lean Six Sigma methodology (instead of Six Sigma) works best in the service industry, showing great results, from doing the basics right, as well as cutting down waste and variations in the end-to-end process.

Check out more about Six Sigma, Lean Six Sigma and eighteen different business process improvement techniques here.

I shall discuss more FAQs concerning effective & efficient business process improvement in upcoming parts of this blog post series...

By the way, if you run a company that is facing a challenge to thrive in these difficult times, I would suggest that you please revisit your business processes in order to accelerate growth and bring a quick turnaround.

Related reading:

- Kaizen for pharmaceutical, medical device and biotech industries.

- Business process improvement techniques for manufacturing and service industries.

- How to choose a business process improvement technique for your organization.

- 30 Popular continuous improvement tools.

- YouTube #Shorts videos on Continuous Improvement.

#businessprocessimprovement #sixsigmamethodology #whatissixsigmamethdology #sixsigmaexplained #sixsigma

#businessprocessmodification #businessprocessreengineering #processimprovement #continuousimprovement #Japanesecontinuousimprovement #businesstransformation #businessturnaround