In this post I'll cover how to find the right team, manage execution, and track performance. So let's get started...

Finding the right team

One of the biggest challenges facing a new biopharma startup is finding the best team. It can be difficult to attract top talent, especially when you're a small startup without a proven track record. To attract top talent, you must offer competitive compensation. Smaller startups often struggle to offer competitive compensation, while larger organizations are often more willing to offer generous benefits packages and equity compensation.

While leading a biotech startup is a challenging role, there are some factors that can help you overcome these challenges and build a strong company culture. First of all, it's important to recognize that the corporate culture will affect the work being done. While companies will always have a culture, it's important to intentionally build a positive and productive one. Developing a positive culture means identifying your strengths and leveraging them to make decisions based on core values and knowledge.

Your co-founders are an important part of your team. In addition to bringing in valuable experience, it is important to share a vision for the company and identify the core values of each team member. These values could include business acumen, healthcare experience, and technical skills. Using networking platforms to recruit co-founders is a great way to find a team that shares your vision.

Creating a team with the right skills is an essential part of a biotech company's success. While the biotech industry is experiencing an incredible time, finding the right talent to translate these innovations to reality is an ongoing challenge. A recent published survey report stated that 51 percent of CEOs in life sciences and pharmaceuticals companies mentioned- Finding the right people is one of their biggest challenges.

I have a separate post on ‘Best practices for biotech talent management’. You may check it out here. And here’s a post giving Best practices for talent management in pharma companies.

Finding the right team is essential when you're trying to compete with the big players. It's essential to have the right mix of people with relevant experience in sales, marketing, and research and development. It's also crucial to be able to hire people with the right technical skills, such as engineers, statisticians, and data analytics.

Managing execution

Managing execution challenges is an important part of leading a new biopharma Startup. As a company grows and its goals change, execution expertise becomes increasingly important to achieve those goals. Fortunately, the biotech community has many resources to help new startups navigate the execution challenges that come with bringing a new biopharmaceutical to market.

Tracking performance

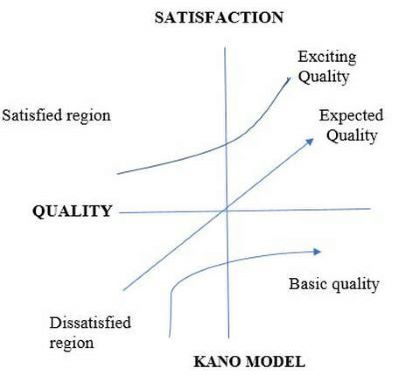

Tracking performance is critical to the success of any biopharma Startup. It can be challenging to measure the impact of key decisions, especially in the R&D phase of a new biotech. The process may take years; that's why it's crucial to include the right information and discussion in key decisions.

Today's biopharma companies are in the midst of a transformation. Digital technologies are driving new processes and reducing time to market. A global pandemic has increased the importance of these next-generation capabilities. These capabilities include more efficient manufacturing, process automations, more effective supply chains, more efficient and flexible networks, and more. They also allow biopharma companies to pursue new value through M&As and patient engagement ventures.

Creating a company culture

Creating a company culture for a biotech Startup is an important step towards achieving sustainable success. It's crucial to build a cohesive team and ensure that the culture reflects the values of the company. Employees feel more engaged when they feel that the leadership is transparent and demonstrates their commitment to the company mission. It's also important to share goals and objectives with the team.

- How to Bring in Organizational Culture Change

- What Role Does Culture Play in Business Transformation?

Companies that focus on creating a strong company culture have a greater chance of success than those that ignore it. An unfavorable corporate culture can lead to high turnover and burnout among employees, which in turn leads to a less-productive organization. A positive company culture is marked by a high level of employee satisfaction and a healthy, stimulating environment. Employees who feel valued are more likely to stay with a company, which in turn attracts top talent.

It is important to create a company culture that emphasizes innovation. Innovation requires continuous improvement and new ideas. Innovation promotes progress on a company and individual levels. A company culture that encourages experimentation and constant learning is an ideal environment for innovation.

In addition to a strong company culture, it's important to hire people with diverse backgrounds and experiences. A well-rounded employee can bring a unique perspective to the company, and their diverse experiences can help them adapt to changing roles. While working in silos in Big Pharma may result in specialized skills, working in diverse parts of the organization can foster humility and a fresh perspective.

Creating a company culture is not easy. It requires a commitment by the senior management team to model the mindsets and behaviors they want. They should also provide ongoing coaching and engage teams in capability building. This approach can be highly effective in creating a shared culture and helping the company achieve its goal.

Building a biotech company requires a dynamic, ever-growing team. To succeed, the company should be able to attract motivated team members and build shareholder value. Furthermore, the company must be able to implement a business model that encourages growth and is easy to execute.

Related Reading:

- Kaizen for pharmaceutical, medical device and biotech industries

- How to cut costs strategically using Kaizen

- Streamline processes and workflows with Gemba Walk.

- Top Ten Strategic Decision-Making Tools for Operational Excellence

Follow Shruti on Twitter, Facebook, YouTube, LinkedIn

Categories: Biotechnology | Operational Excellence | Leadership

Keywords and Tags:

#operationalexcellence #operationalexcellenceforbiotechindustry #strategymanagement #strategicplanning #leadingbiotech #workculture #bestpracticesinbiotech #managechange #culturechange #startup #biotechstartup #digitaltransformation