In today's fast-paced and data-driven world, organizations are constantly seeking ways to improve their processes to increase operational excellence.

Hence, regardless of industry sector, process improvement projects are on the rise, thus keeping project management teams super busy. Therefore, like any other department in an organization, for project management function too, continuous improvement is vital.

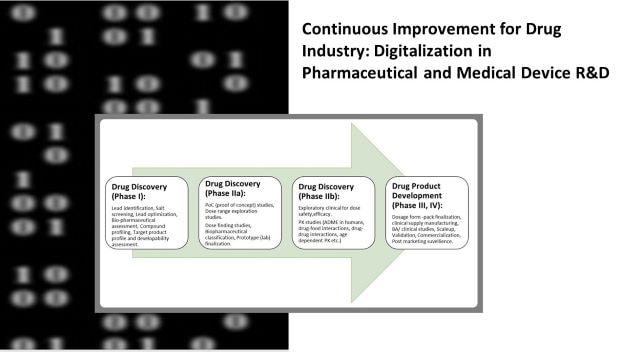

One of the key continual improvements in the project management function is digitalization. Traditional project management approaches have served us well. But the rise of artificial intelligence (AI) application in project management is recalibrating the landscape of process improvement campaigns.

Today, AI is not just a buzzword; it's a revolutionary driving force that is set to transform how we plan, execute, and monitor process improvement initiatives. In this blog post, I shall delve into the profound ways AI is redefining management of process improvement projects, and why it's essential for businesses to embrace this transformative technology.

1. Data-Driven Decision Making

AI's primary strength lies in its ability to analyze vast amounts of data quickly and accurately. In management of process improvement projects, this translates to data-driven decision making. You may want to checkout Top ten decision-making tools for operational excellence here.

AI can sift through historical project data, identify patterns, trends and provide actionable insights. This empowers project managers to predict potential roadblocks, make informed decisions and optimize project management effectively, which results in efficient and successful project outcomes. Also, the process improvement projects get handled successfully, within the scope- cost- time outline.

2. Predictive Analytics

Predictive analytics is one of the most exciting AI applications in process improvement project management. AI can forecast potential bottlenecks, resource constraints as well as project risks based on both historical data and real-time information. This facilitates project managers to proactively address challenges before they become major setbacks. By utilizing AI's predictive capabilities, organizations can stay one step ahead in managing projects effectively and efficiently.

3. Automation and Efficiency

AI is a game-changer when it comes to automating routine tasks, especially the repetitive and time-consuming activities. Hence, such activities which tend to bog down project workforce and drain efficiencies can now be assigned to AI-powered tools and bots. This will free-up valuable time and resources for the project team, that can be redirected towards higher-value project management tasks. Automation will ensure that project management processes will run smoother and more efficiently, reducing the risk of human error.

4. Enhanced Resource Allocation

One of the critical aspects of project management is resource allocation. AI can assist in optimizing resource allocation by analyzing project requirements, workforce skills, capability, and availability. It ensures that the right people get assigned to the right tasks, thus improving project efficiency, and ultimately leading to cost savings. Additionally, AI can help to identify over- or underutilized resources, and enable better skill governance and workforce management.

5. Real-Time Monitoring and Reporting

AI-driven dashboards provide real-time monitoring and reporting capabilities, empowering project managers to track progress, identify deviations, and take corrective actions promptly. This level of visibility into project performance enables project managers to make on-the-fly adjustments (without any scope creep), ensuring that projects stay on track and meet their objectives.

6. Personalized Insights

AI can provide personalized insights and recommendations to individual project team members, offering guidance on their specific tasks and responsibilities. This not only improves productivity but also prevents oversight. Also, it motivates the project team and enhances collaborative working. In fact, each team member can create a tailored roadmap for their contribution to the project's success and growth.

7. Risk Management

Risk management is one of the key aspects of effective project management and AI’s ability to swiftly analyze huge amounts of data facilitates in comprehensive risk assessments early on. This allows project managers to take proactive measures at risk mitigation and prevent chances of potential project failures. Further, AI can suggest suitable risk mitigation strategies based on historical data and predictive analytics, thus increasing the likelihood of successful project outcomes.

Conclusion

The impact of AI on management of process improvement projects is undeniable. AI has transformed the way projects are handled end-to-end. From data-driven decision-making to predictive analytics, automation, and personalized insights, AI has equipped project managers with the tools they need to succeed in their tasks. And as AI continues to advance in its role, its impact on project management will get more profound. Therefore, organizations that embrace AI and incorporate it into their project management best practices will gain a competitive edge, delivering higher quality projects more efficiently.

AI is no longer the future; it's the present, and those who harness its power will lead the way in operational excellence.

Related Reading:

- Top Ten Strategic Decision-Making Tools for Operational Excellence

- Popular Continuous Improvement Workshops & Webinars for Manufacturing Industries

- What is Machine Learning?

- Popular Continuous Improvement Tools.

Follow Shruti on Twitter, Facebook, YouTube, LinkedIn

Categories: Process Improvement | Operations | Digitalization

Keywords and Tags:

#DrShrutiBhat #ProcessImprovement #ProcessExcellence #ContinuousImprovement #OperationalExcellence #ProjectManagement #AI #Digitalization #DigitalTransformation