Few important decisions to make for effective tech-transfer may be- when to commence first production batch or whether to produce in-house or outsource. Larger the organization, longer is the time for decision making and elaborate the process.

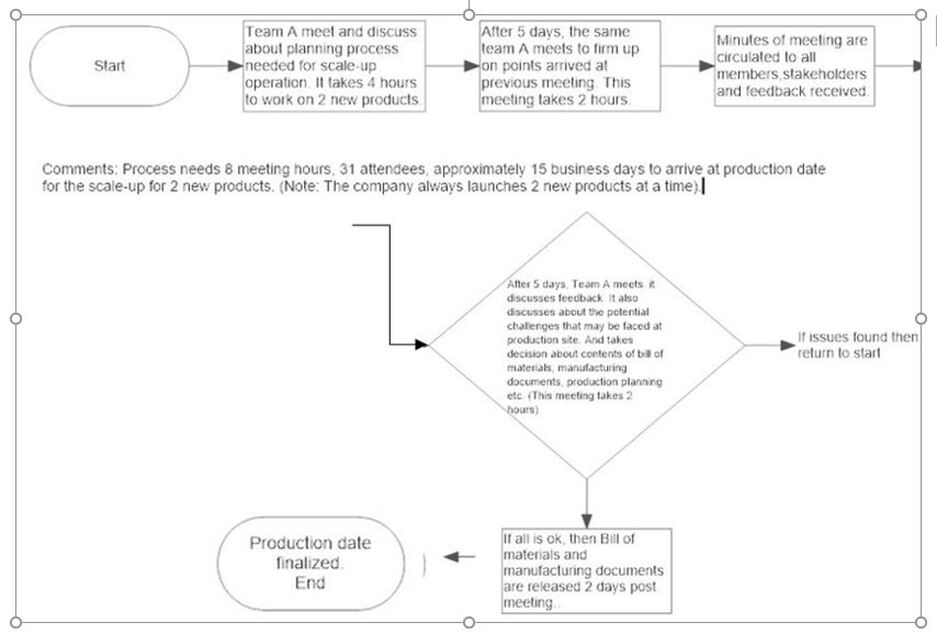

In this case study, the company’s existing scale-up process needed meeting attendance of 31 members, who used up 15 business days to finalize a production date!

- Decrease members attending from existing 31 to 9. Only members close to the process shall attend the ; everyone else to receive minutes of meeting for information. The new list of attendees (B) would include- Design scientist, Lab Head, Analytical chemist, Procurement Manager, Manufacturing Supervisor, QA Manager, Production planner, one member from the team and Project Leader.

- Number of days to achieve key process output to be reduced.

Existing process map-

Set up a sub-team, headed by Kaizen Champion to study the existing process via process stapling. They also interviewed several employees in various departments such as R&D, manufacturing, testing lab, quality, packaging, business development etc.

A Kaizen event was scheduled to generate process improvement ideas.

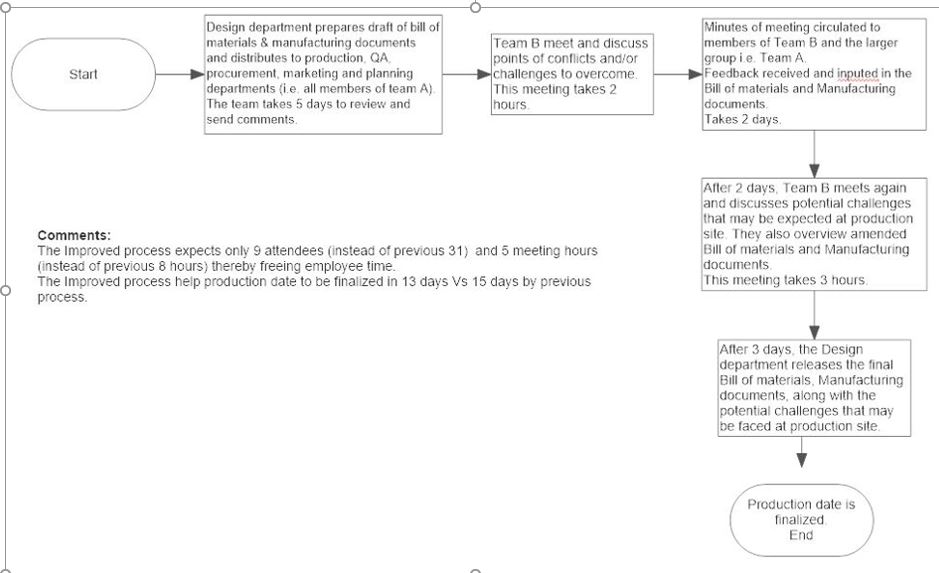

Brainstorming, SIPOC, Arrow diagrams, Decision trees and other tools were employed. The proposed ‘improvement’ workflow was communicated to all stakeholders for their suggestions/ recommendations and later finalized. Below is the workflow chart of the new ‘improved’ decision making process.

Improved process (map)-

Kaizen Event Result Dashboard:

The improved process needed only 9 meeting attendees (instead of 31) and 5 meeting hours (instead of previous 8 hours) thereby freeing more number of employee hours for constructive work. The improved process helped production date to be finalized in 13 days Vs 15 days via old process. Further, the Kaizen event generated 14 % savings in company’s overhead costs in the first year followed by 9% savings year on year, till date.

Follow Shruti on Twitter, Facebook, YouTube, LinkedIn

#Manufacturing #Lean #ContinuousImprovement #Kaizen #QualityImprovement #ManufacturingManagement #LeanInnovation #Pharmaceutical #LifeSciences #KaizenLeaderMasterclass #Kanban #FMEA #RiskManagement